Joe Foster co-founded Reebok in 1958 and helped grow the company’s value to $4 billion before exiting in 1991 (Adidas acquired Reebok in 2005 for $3.8 billion, and later Sold in 2021).

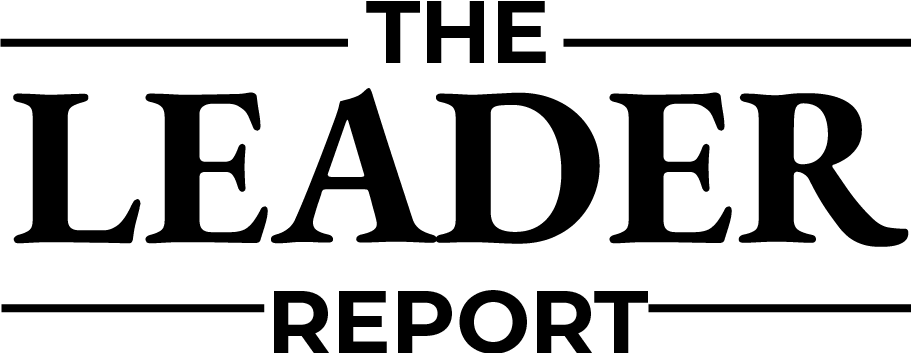

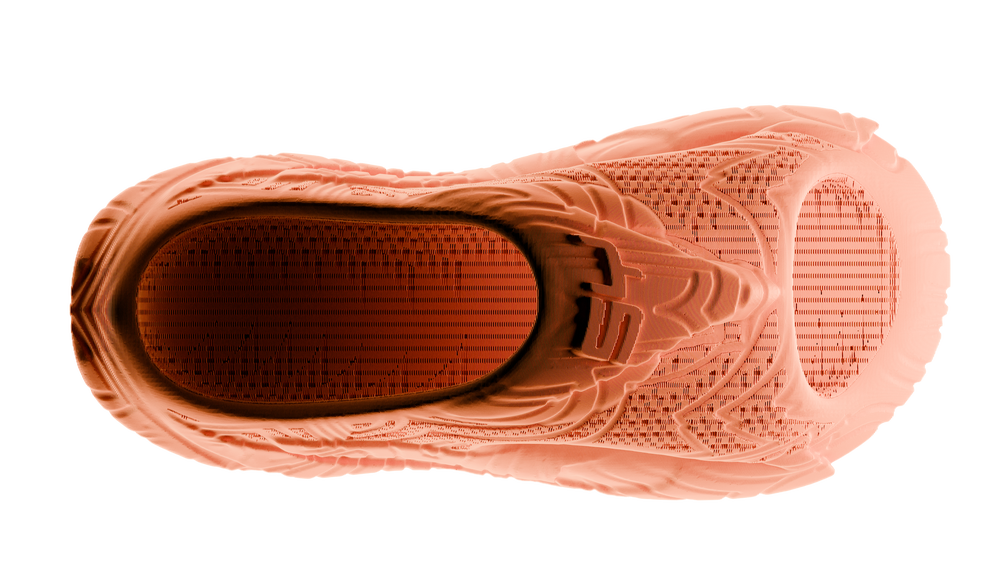

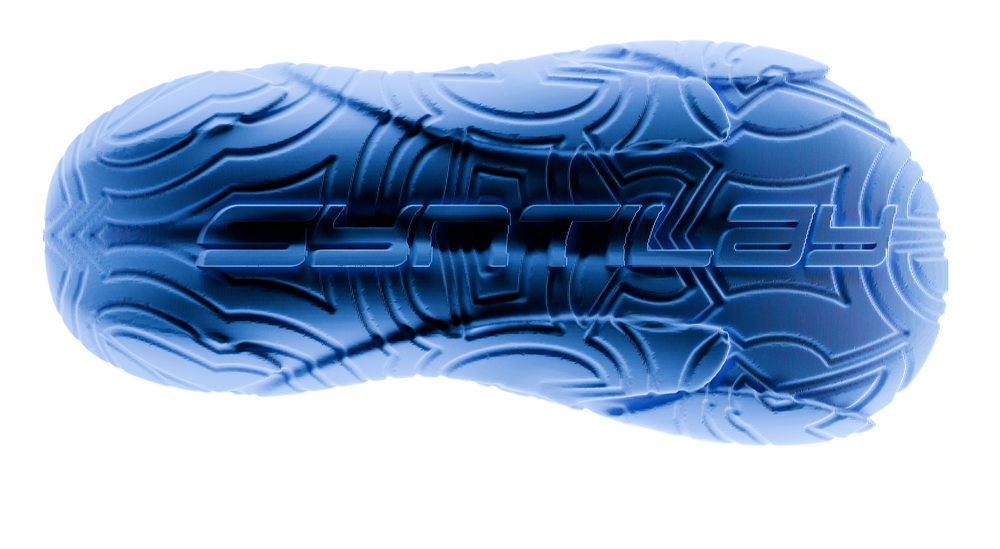

Now, the 89-year-old entrepreneur is helping launch a new high-tech shoe brand with fully 3D printed slides. This means that the slides are printed out rather than assembled sequentially from stacked layers of plastic filament.

This is also the first commercially available shoe designed by AI, the founders told Entrepreneur.

Credit: Sintilei

The shoe is the first from Syntilay, a brand Foster advises. Syntilay’s founder and CEO is Ben Weiss, a 25-year-old serial entrepreneur who has previously released a weekly podcast, an NFT company, and a sneaker brand.

Weiss & Foster began its slide into the lucrative U.S. footwear market on Thursday, according to RunRepeat. This market generated approximately $78 billion in revenue in 2021 and is projected to reach $104 billion in 2028.

The shoes come in five colors: blue, black, red, beige, and orange, and are custom-made for each purchaser.

RELATED: This 27-year-old started a side hustle on Facebook Marketplace – and now makes more than $500,000 a month doing it

Weiss and Foster produced a few thousand pairs, enough to make the Syntilay name even more recognizable, and then shifted gears to create a unique, AI-designed product that brands and content creators can sell as their own. He said he plans to create shoes.

The entrepreneur spoke to the founders about how he got into the business, how AI has contributed to shoe design, and what Foster learned from Reebok.

How did this partnership begin?

Foster: Ben (Weiss) came to us with an idea. I think it was Ben’s enthusiasm that inspired us. This partnership has been in the works for 18 months.

Weiss: I reached out to him, and a few months later we met in person and had a nice chat. We have discussed the opportunity here.

These slides do not have traditional sizing. How do people achieve custom fits?

Weiss: The shoes are scanned and fitted via your phone’s camera app. Our partner Zellerfeld is driving this approach. They have a great way to find the perfect shoe for you by taking measurements from your phone’s camera and 3D printing them specifically.

Related: We tried 3 AI headshot generators and there was a clear winner

Could you tell us more about the design of the shoes?

Weiss: The design is quite unique in that the shape was generated using AI. That was the inspiration for what we built. We had a (human) designer create a sketch, from which the AI generated a 3D shape. All shoe patterns are also designed by AI. We have generated a pattern. We’ve tried lots of different versions of it. Very detailed.

So, as a shoe designer, do you believe in AI, or was there more human involvement?

Weiss: I think there’s a lot of disagreement. This is the most AI-designed shoe ever made. These are truly AI shoes. We still relied on human designers to help us create and guide us along the way. I think that’s probably the best thing you can do at the moment.

RELATED: Here’s how much it costs to own a 3D printed ‘fortress’ home in Texas

What are the advantages and disadvantages of 3D printed shoes?

Foster: The advantage is that it speeds up development. We can produce your product within a few days, and if we make a mistake, you can get a new sample. This makes development much faster. Well, we are still learning how much it can be developed and what the process is. The downside is that you can’t 3D print in large quantities, but you can bring your product to market and make sure it does what it does.

Side view of red slide. Credit: Sintilei

What lessons did you learn at Reebok and how do you plan to apply them here?

Foster: Sometimes there are problems, sometimes there are challenges, but I’ve learned that those challenges are opportunities. We started our business as Mercury Sports Footwear. I couldn’t register it, so I thought of a better name. Also, the silhouette had to be changed because Adidas didn’t like the two stripes and T-bar. I changed it to the vector you see in Reebok today. I think this applies to anything I do. If you’re in business, you need to be ready and willing to change. In fact, you should look for change. And if someone challenges you, that’s a good time.

How do you want to scale Syntilay?

Weiss: We’re starting with different colorways of this shoe right now, but this is a pretty limited run overall. Ultimately, we want to encourage more brands and content creators to try out footwear. What we have today is a way to manufacture shoes faster using artificial intelligence and 3D printing. Our approach is to create completely new and original designs for brands and influencers.

What is the end goal of this launch?

Foster: It took 10 years to bring Reebok to America. But that changed when it received a 5-star rating from Runner’s World. They wanted us back then – America wanted Reebok. Gained credibility. Somewhere along the way, Syntilay will gain credibility. It could be very simple. It may be one person. All that matters now is getting this shoe out there and making people think, “Wow, this is great.”

This interview has been lightly edited and cropped for clarity.

RELATED: When his father died, he went to the mall to grieve and shopped for sneaker sales. Now his hobby is a $10 million side hustle.